All You Need to know about Predictive Maintenance using Machine learning.

One of the most effective defination methods of keeping track of the likelihood of system failures in the near future and planning maintenance is to use predictive maintenance company. While system failure is an extremely common problem that can occur in any device, it is vital for every computer or software program to recognize the issue and act to prevent it. Failure of systems explanation can significantly impact all TPM aspects of life in the present time when we are totally dependent Advantage on computers and IOT machines. When we talk about industry 4.0 organizations that are affected by system failure, it can result in substantial financial software losses. However, if we consider Predictive Maintenance Machine Learning changing analysis the remedial or preventative condition processes plants and procedures, we are able to predict the production failures. In such a case we could simply prevent artificial these issues and prevent the entire system provider from crashing, which is the point where predictive condition-based maintenance can be a factor. We’ll learn about pre-planned maintenance programs (PMS) and the ways they work to identify failures, different remedial measures to prevent system problems, techniques for machine learning to predict maintenance, the advantages proactive of incorporating machine-learning into predictive maintenance monitoring and more. This is the topic, “Predictive maintenance using machine learning.” So, let’s start with an overview of predictive maintenance.

Predictive Maintenance: What Is It?

Monitoring a Advantage structure or part of an equipment’s operation during the time it is being used is called predictive maintenance. The data is collected over time to monitor the state of the production equipment and detect any potential plants problems so that they can be addressed before a malfunction occurs.

The discovery of defination trends that could help in the prediction of machine malfunctions, and eventually, their reduction is the main purpose for predictive maintenance. The techniques used to predict maintenance include, for instance the analysis of vibrations as well as oil analysis thermal digital imaging, monitoring of equipment explanation and more.

Making use of machine learning to help predict maintenance

Predictive maintenance permits you to perform automatic data processing on an experimental or your company data set even though it’s an approach to correcting the chance of failure in systems when used in conjunction using machine learning. The predictive use of machine learning aims to spot patterns in system failures through taking data scientist lessons from previous analysis experience or production data from the past.

While machine learning could solve a variety of issues associated with maintenance tasks like unplanned breakdowns or unexpected issues, the general approach to maintenance that is predictive has some condition drawbacks. This is why it can help to maximize automation maintenance and prevent negative consequences in the event of an IOT unexpected defination interruptions.

Make use of predictive maintenance as…

The purpose of predictive maintenance is to spot imminent system flaws. It also ensures that we don’t need to perform maintenance frequently. This can also help save time and costs. Today, businesses are using predictive analytics software to assist with monitoring equipment, which aids in the planning of maintenance and repairs that will keep the TPM equipment in good condition. Predictive maintenance also enhances OEE and overall efficiency of the equipment.

Machine learning-based predictive maintenance methods could address a variety of maintenance-related issues, like unexpected breakdowns. Therefore, it’s important to study this type proactive of connection provider to improve condition-based maintenance processes and avoid negative artificial impacts during times of unplanned digital downtime.

Applications of Machine Learning for Predictive Maintenance

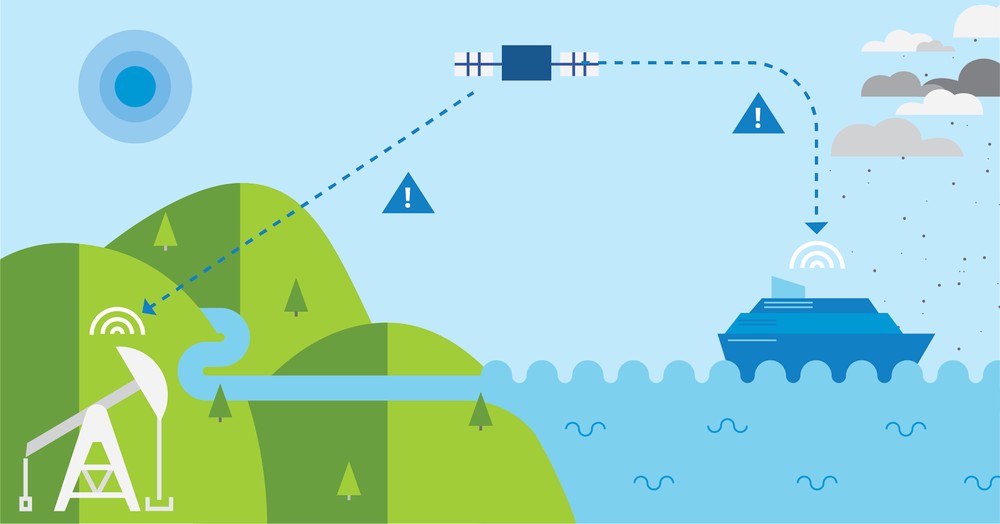

The main purpose in predictive maintenance is detect imminent Advantage system flaws and fix them by taking the appropriate action to fix them. We can analyze a large quantity explanation of information using the machine-learning and prescriptive maintenance techniques to discover any actual condition potential issues that could result in different kinds of commercial and monetary losses. Machine learning can be used in a variety of ways to predict maintenance needs, such as for industrial facilities, trains, power plants aviation as well as petroleum and natural gas industries logistical and company transportation, etc.

Manufacturing and IoT: Predictive maintenance is commonly employed in the manufacturing industry to track the manufacturing process by quickly monitoring identifying any issues and then removing them with IOT. This improves the efficiency of manufacturing processes overall.

Automobiles and automotive: There are a variety of technologies or software that connect vehicles to sensors that dealers or plants manufacturers have already activated Predictive Maintenance Machine Learning in their analysis automobiles. The sensors collect all information and create massive quantities of data, which can be immediately automation accessible to dealers or manufacturers data scientist. They inform us of possible industry 4.0 failures and suggest solutions prior to the occurrence.

Utility Service Providers: Predictive Maintenance approaches help system utility companies provider complete internal tasks with greater efficiency by predicting monitoring the onset of demand, supply, and outage problems.

Insurance: Many banks and financial institutions employ predictive maintenance techniques and software to accurately predict the production probability of severe weather-related events.